Awọn ẹya alloy Titanium Tirakito Apakan/Ẹrọ Iyanrin Irin / Irin Iyanrin / Mechanical / Awọn ẹya mọto fun Ara Compressor

| Ohun elo | Aluminiomu: AL6061, Al6063, AL6082, AL7075, AL5052, AL2024 |

| Irin alagbara: SS201, SS301, SS303, SS304, SS316, SS430 ati be be lo | |

| Irin: ìwọnba, irin / erogba, irin pẹlu 1010, 1020, 1045, 1050, Q690 ati be be lo | |

| Idẹ: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 ati be be lo. | |

| Ejò: C11000, C12000, C12000, C17200, C72900, C36000 ati be be lo. | |

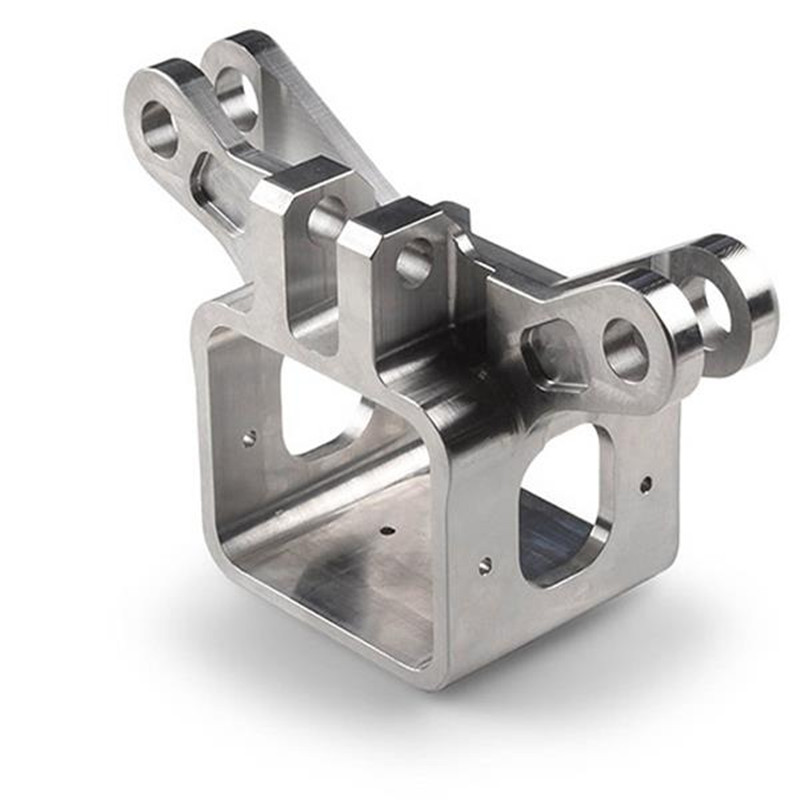

| Ṣiṣẹda | Germany Trumpf brand Laser ojuomi, ẹrọ irẹrun CNC, ẹrọ atunse CNC, |

| (CNC) ẹrọ isamisi, Ẹrọ Hyraulic, Ẹrọ alurinmorin oriṣiriṣi, CNC ẹrọ aarin. | |

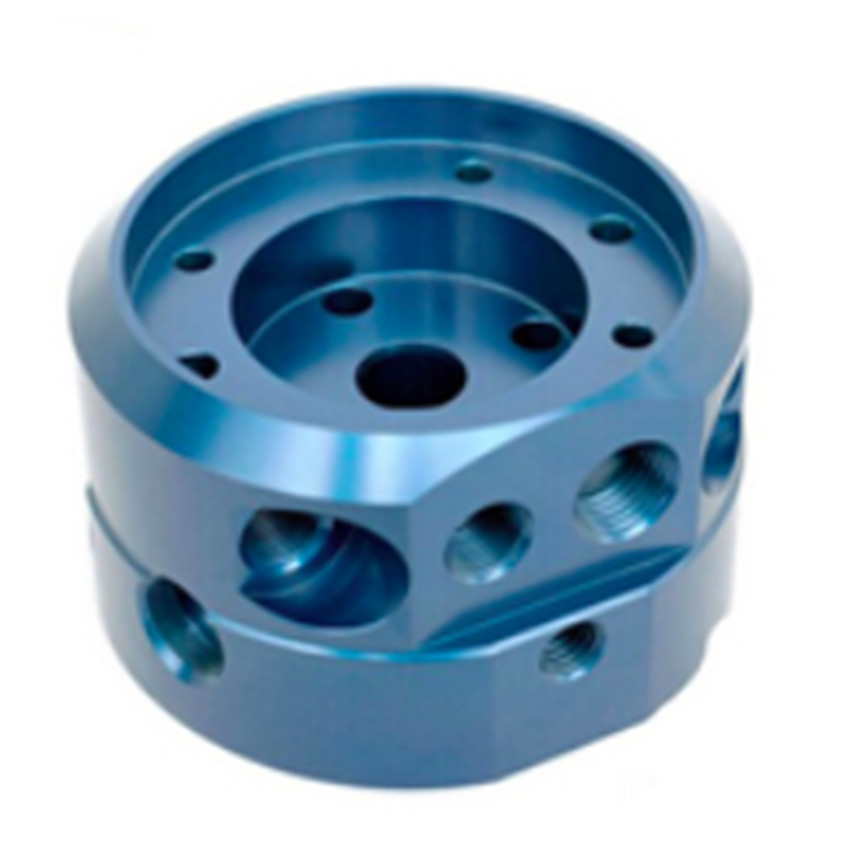

| Dada | Aluminiomu: Anodization, Sandblast, Brushing, Polishing, Electro-plating etc |

| Irin alagbara: didan, Brushing, Passivating, Sandblasting, Electro-plating | |

| Irin: Zinc plating, Nickel plating, Chrome plating, Powder Coating, Painting etc | |

| Idẹ & Ejò: Brushing, Polishing etc | |

| Itọkasi | + - 0.1mm |

| Ohun elo | Railway, Auto, Truck, Medical, Machinery, Equipment, Electronic, Electrical etc |

Titanium jẹ iru tuntun ti irin.Išẹ ti titanium jẹ ibatan si akoonu ti awọn aimọ gẹgẹbi erogba, nitrogen, hydrogen ati atẹgun.Awọn akoonu ti impurities ninu awọn purest titanium iodide jẹ kere ju 0.1%, ṣugbọn awọn oniwe-agbara ni kekere ati plasticity jẹ ga.Awọn ohun ini ti 99.5% ise titanium mimọ ni o wa bi wọnyi: iwuwo ρ = 4.5g / cm3, yo ojuami 1725 ℃, itanna elekitiriki λ = 15.24W / (mK), agbara fifẹ σb = 539MPa, elongation δ = 25%, apakan isunki ψ = 25%, modulus ti elasticity E = 1.078 × 105MPa, lile HB195.

Agbara giga

Awọn iwuwo ti titanium alloy ni gbogbo nipa 4.51g / cm3, nikan 60% ti irin, ati diẹ ninu awọn ti o ga agbara titanium alloys koja agbara ti ọpọlọpọ awọn alloy igbekale steels.Nitorina, awọn kan pato agbara (agbara / iwuwo) ti titanium alloy jẹ Elo tobi ju ti awọn ohun elo igbekalẹ irin miiran, eyiti o le gbe awọn ẹya pẹlu agbara ẹyọkan ti o ga, rigidity ti o dara ati iwuwo ina.Awọn paati ẹrọ ọkọ ofurufu, egungun, awọ ara, awọn fasteners ati jia ibalẹ gbogbo lo alloy titanium.

Agbara igbona giga

Iwọn otutu lilo jẹ awọn iwọn ọgọrun diẹ ti o ga ju alloy aluminiomu, tun le ṣetọju agbara ti a beere ni iwọn otutu alabọde, le ṣiṣẹ fun igba pipẹ ni iwọn otutu 450 ~ 500 ℃.Awọn iru meji ti titanium alloy ni 150 ℃ ~ 500 ℃ ibiti o tun ni agbara kan pato ti o ga julọ, ati aluminiomu aluminiomu ni 150 ℃ kan pato agbara dinku significantly.The ṣiṣẹ otutu ti titanium alloy le de ọdọ 500 ℃, nigba ti ti aluminiomu alloy ni isalẹ. 200 ℃.

Ti o dara resistance to ipata

Awọn ipata resistance ti titanium alloy jẹ Elo dara ju ti irin alagbara, irin ni tutu bugbamu re ati omi okun.Pitting ipata, acid ipata, wahala ipata resistance jẹ paapa lagbara;O ni o ni o tayọ ipata resistance to alkali, kiloraidi, chlorine Organic awọn ọja, nitric acid , sulfuric acid, ati bẹbẹ lọ.Ṣugbọn ipata ipata ti titanium lati dinku atẹgun ati alabọde chromium ko dara.

Ti o dara kekere otutu išẹ

Titanium alloy le ṣetọju awọn ohun-ini ẹrọ rẹ ni awọn iwọn otutu kekere ati ultra-kekere.Titanium alloys pẹlu iṣẹ iwọn otutu kekere ti o dara ati awọn eroja interstitial pupọ, gẹgẹbi TA7, le ṣetọju ṣiṣu kan ni -253 ℃.Nitorina, alloy titanium tun jẹ pataki pataki. kekere otutu igbekale ohun elo.

Iṣẹ ṣiṣe kemikali giga

Titanium alloy awọn ọja

Titanium alloy awọn ọja

Titanium ni o ni kan to lagbara kemikali lenu pẹlu O2, N2, H2, CO, CO2, omi oru, amonia ati awọn miiran gaasi ninu awọn bugbamu.Nigbati erogba akoonu jẹ tobi ju 0.2%, lile TiC yoo wa ni akoso ninu awọn titanium alloy.Nigbati awọn otutu ni ga, awọn lile dada Layer ti TiN yoo wa ni akoso nipasẹ awọn ibaraenisepo pẹlu N.Nigba ti awọn iwọn otutu jẹ loke 600 ℃, awọn titanium absorbs atẹgun ati ki o fọọmu kan àiya Layer pẹlu ga hardness.Bi awọn hydrogen akoonu ga soke, a brittle Layer yoo. tun form.The ijinle ti awọn lile ati brittle dada Layer ti a ṣe nipasẹ awọn gbigba ti gaasi le de ọdọ 0.1 ~ 0.15 mm, ati awọn hardening ìyí jẹ 20% ~ 30%.Titanium kemikali ijora jẹ tun tobi, rọrun lati gbe awọn adhesion pẹlu awọn edekoyede. dada.

Kekere itanna elekitiriki elasticity

Imudara igbona ti titanium (λ = 15.24W / (m · K)) jẹ nipa 1/4 ti nickel, 1/5 ti irin, 1/14 ti aluminiomu, ati imudara igbona ti awọn oriṣiriṣi titanium. Alloys jẹ nipa 50% kekere ju ti titanium.The rirọ modulus ti titanium alloy jẹ nipa 1/2 ti irin, ki awọn oniwe-rigidity ko dara, rọrun lati abuku, ko yẹ ki o ṣe ti slender opa ati tinrin-odi awọn ẹya ara, gige nigbati awọn processing ti awọn dada ti rebound jẹ nla, nipa 2 ~ 3 igba ti irin alagbara, irin, Abajade ni àìdá edekoyede, adhesion, alemora yiya lori awọn ọpa dada.